As businesses continue to face complex challenges and disruptions through factors such as climate change, the economy, conflict, and unprecedented events like COVID-19, the importance of a resilient and adaptable supply chain cannot be undermined.

More often than not, a well-orchestrated, strategy-led supply chain lies at the heart of every successful business.

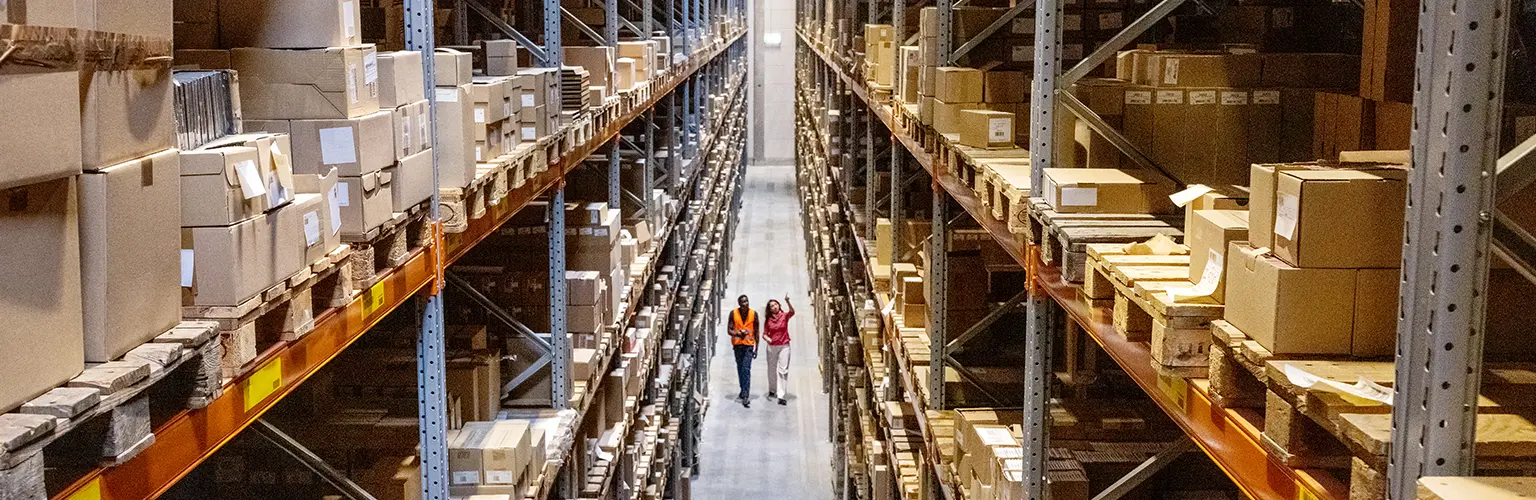

Successful supply chain management involves the coordination of resources, information, staff and activities so that every aspect of the chain operates smoothly, from the first step of sourcing raw materials, to the end step of delivering finished products to customers.

But with the increasing disruptive nature of the 21st century business landscape, how can leaders future-proof their supply chain to mitigate risk and continue to drive organisation success?

Reject the one size fits all approach

The first aspect of creating an effective supply chain which leaders must understand is that every business is unique and a customised supply chain is key. When first starting out, it might be tempting to try and replicate other successful businesses’ supply chain models, but doing so fails to account for the unique complexities and nuances that characterise individual businesses and the industries they work within.

By embracing a tailored approach when mapping out their supply chain, organisations can focus on their own operational intricacies and design strategies that maximise their efficiency, resilience, and competitive advantage.

This customised approach also enables businesses to adapt to changing environments, mitigate risks, and capitalise on emerging opportunities, increasing their chances of growth and success.

Embrace digital transformation

Harnessing the power and ever-evolving abilities of technology is without a doubt one of the most fundamental components of creating a resilient supply chain.

Advanced analytics, artificial intelligence, automation technology, and blockchain are just some examples of how digitalisation is revolutionising the way supply chains operate.

Because of this, leaders are able to optimise their operations and processes, easily identify inefficiencies, and mitigate risks at a much earlier stage.

Digital transformation also encourages operational agility and responsiveness, allowing businesses to adapt quickly to changing market conditions and customer demands.

Stress-test your supply chain

Stress testing involves assessing the resilience and vulnerabilities of the supply chain under various scenarios, including disruptions, market fluctuations, and unexpected events.

By subjecting supply chains to rigorous testing, businesses are able to identify potential weaknesses, anticipate risks, and implement proactive measures to enhance resilience.

This proactive approach not only minimises the impact of disruptions, but also allows businesses to adapt swiftly to changing conditions and maintain operational continuity.

Avoid under-estimating logistical costs

Logistical expenses involve a wide range of factors, including transportation, warehousing, inventory management, and distribution.

Failing to accurately account for these costs can lead to budget overruns, diminished profitability, and operational inefficiencies.

Building a comprehensive understanding of costs will help businesses identify opportunities for streamlining their operations, explore where they could benefit from negotiations with suppliers, and where to optimise resource allocation, all of which contributes to improving overall supply chain performance.

Implement sustainable practices

Sustainability is no longer thought to be a buzzword used by a handful of forward-thinking businesses, but a fundamental component for businesses across the globe.

Integrating sustainable practices into operations by considering environmental, social, and economic factors throughout the entire value chain will not only help to improve the environmental footprint of businesses, but it can also strengthen brand reputation, as consumer and stakeholder values continue to point towards sustainability and protecting the environment.

From ethical sourcing and renewable energy initiatives to waste reduction and circular economy principles, businesses can future-proof their supply chains while creating long-term value for themselves, society, and the planet.

Creating an agile, sustainable, and resilient supply chain management strategy is by no means an easy task, but by considering these strategic elements, senior leaders can begin to navigate the complexities of modern-day supply chains with confidence and flexibility.