On May 2019, The Innovation Management and Entrepreneurship (IME) paid a little visit to the Graphene Engineering Innovation Centre (GEIC) at the heart of Manchester. Do you know that The University of Manchester is the world-leading research and innovation ecosystem for graphene? The graphene institute itself literally just a few steps away from the university! If you ever heard of graphene, you already know that it is a very special discovery and we are here to know all about it!

The IME entourage was welcomed by the CEO of Graphene@Manchester himself, James Baker, which explained everything that we need to know about this new and exciting material!

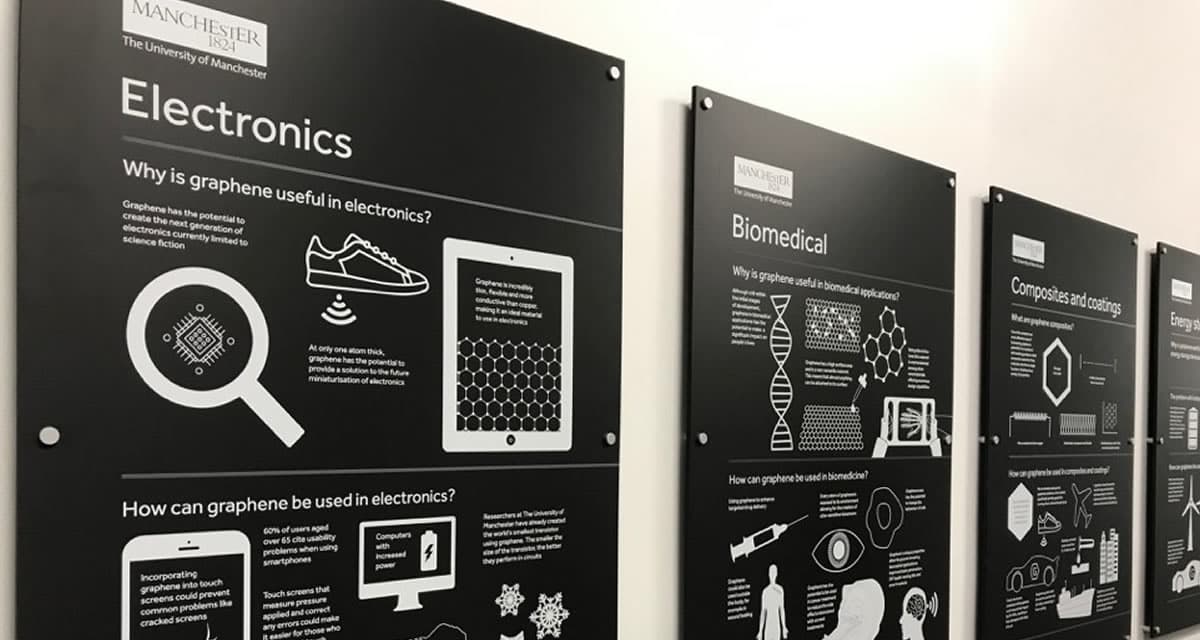

Graphene was a two-dimensional sheet of carbon atoms that can be used in a wide range of fields from engineering to biomedicine. Graphene was first discovered in 2004 by two researchers at The University of Manchester which led to the Nobel Prize in physics for their work. What makes graphene so special is, it is known as the strongest material with a variety of features from flexibility, to heat and electricity conduction that makes it filled with vast potential in the industry. Due to its durability and flexibility, graphene can be applied to enhance the performance of a variety of products! Currently, graphene starts to be used in sports equipment, shoes and clothing. Part of what the graphene institute does is testing and comparing the graphene infused products to the conventional products. It is found that graphene has proven to increase the product's durability by around 5% to 20% and also able to save production time and resource which means more environmentally friendly production!

Graphene material has caught the attention of many big companies that are eager to enhance their product performance. One of the main factors that support its adoption process, apart from its relative advantage compared to the existing material, is its trialability and observability. Graphene is currently under experiment for its full potential and application in a wide range of materials. It is important for the companies to be able to experiment and observe how graphene works on a small scale, in order to assess the risk and complexity of the product before deploying it into full-scale production infrastructure which requires a significant amount of investment. Another reason that makes graphene attractive is its familiarity. Graphene infused products physically do not look any different from any other regular products. This sense of familiarity eases the market adoption process.

We later were shown the factory line facility that processes the graphene as shown in the picture above. This facility looks more like a factory rather than a conventional university laboratory. The reason behind it is because some of the processes to build the graphene induced components require heights and certain plug-in to particular materials. At the back of the facility, also lies a machine that mix graphene with various components such as carbon fibres that usually used for cars, aircraft and the aerospace industry. While the various pipes are used to make the graphene materials and mix graphene into the metal which can be used to improve the energy efficiency of the high-power transmission power lines. Sustainability also plays major consideration in the process. Everything that is extracted and taken out goes through purification and filtration which then will be neutralised before they got into the air or into the water.

We then were shown how Graphene can be made into a membrane that blocks salt, oil or water on a high scale through the machine, which is still in trial as seen above. To start the coating process, the surface such as nylon, wallpaper or any other materials that need to be coated with the graphene membrane, is put at one end of the machine. The material then goes through the machine in a series of treatments, processes and temperatures, which result in coated surface at the other end. If the machine is successfully developed to do as purposed, this can potentially attract commercial business to create alternative packaging, anti-corrosion material or even use the membrane for a battery in the future. By integrating graphene membrane cell into the battery, can solve the challenge of battery capacity by improving its durability and performance. This experiment on the battery is conducted in the special section of the graphene institute called the energy laboratory.

The other part of the facility called the CBD laboratory also experiments in integrating graphene with a roll of copper, which reduces the weight of the copper. The weight reduction would revolutionize the aerospace industry as it results to lower cost and environmental impact. Similarly, in the printing laboratory, graphene powder is mixed into other materials to revolutionise the existing industry. In order to diffuse graphene into the commercial market, it will be difficult to replace all the conventional products. Thus, graphene acts as more of a complementary solution rather than competition to the existing material.

All of these experiments and facility certainly requires high capital. James baker then explains the benefits of graphene development and research for the university. First, the Nobel prize on the graphene work enhances the university's credibility and improve its reputation. In addition, the research and development of graphene creates value by creating potential jobs in the future for the local community, when the material is produced and used on a significant scale. Moreover, it also attracts the best talents to come to the university and work with graphene which certainly enhance the university's capability. Finally, graphene also possesses commercial value by potentially generating revenues through a partnership with big companies, which certainly brings financial benefit. The future goal for the Graphene@Manchester of course to add value for both university and the city of Manchester.

With its promising potential, graphene certainly holds a bright future for Manchester and UK in general. It will be interesting to see the material development and disruptive innovation that it brings to the industry. And it all started right here in our university neighbourhood! It is about time for us to acknowledge our university's breakthrough discoveries and science. You can understand more about graphene on this site.